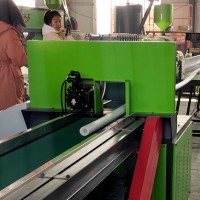

Polyethylene foam film laminating machine unit:

(1)Size of laminating—heating roller:270mm×1600mm

(2)Laminating—Roller Pressure:3-7kg/cm2

(3)Laminating material:surface treatment by teflon

(4)Heating Method:electric heating

(5)There is conducting hot oil inside laminating roller, the conducting effect is very good.

(6)Temperature of hot roller:90-130℃

(7)Materlal of down roller: Rubber Coating

(8)Size of rubber roller:Ф270mm*1600mm

(9)Rubber hardness: HS-A700

(10)Expending roller:100mm×1600mm×1set

(11)Winding method: torque motor control

(12)Driving method:gear box driven by motor,direct transmission,easy operation,safety and beauty.Polyethylene foam film laminating machine

The Polyethylene Foam Film Laminating Machine is designed reasonably and easier to operate . Laminating roller is hardening treatment and sprayed anti-sticking Teflon .Temperature control system adopts precise temperature controller to control and detect. Driving system adopts frequency to adjust laminating speed precisely . Machine is running stably and high efficiently.|

Model |

FM1400 |

FM1700 |

FM2200 |

|

Product width(mm) |

1200 |

1500 |

2000 |

|

Heating method |

Stainless steel rod electric heating |

||

|

Motor Power (KW) |

1.5 |

2.2 |

4 |

|

Installed capacity (KW) |

10 |

15 |

35 |

|

Overall dimension (mm) |

4.5×1.8×1.2 |

4.5×2.2×1.2 |

4.5×2.3×1.2 |