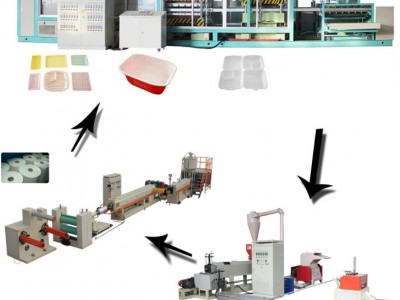

. PS Foam Sheet Extrusion Line

2. Fully Automatic Vacuum Forming Cutting and stacking Machine

3. Crusher and Recycling Machine

This line is the whole production line, which can form lunch box from raw material. This is the recycle. The work flow is as follows: raw material---(ps foam sheet extrusion line)---foam sheet---(lunch box forming machine and cutting machine)---lunch box---(plastic recycle machine)---plastic granulars( this part can be used as raw material)----foam sheet.

This forming and cutting incorporated machine designed by our company is all-powerful. The main way is vacuum forming as well as press forming and synthetical forming. It can be used for forming kinds of plastic sheet. This machine adopt PLC control, it has group possesses reliable stability, large forming area, high production and automatic degree. The machine can mainly forming the PSP materiau bl which is used to produce food container, tray, bowl, cup etc. Forming, cutting, stacking are done in the same machine, saving labor, improving efficient, lowing labor intensity and reducing production cost. Production process is to put foam sheet into forming machine, and product and wastage will come out from the rear part.

Fully automatic mechanical hand PS foam food container making machine is all-powerful thermoforming machine with integrating vacuum forming,cutting off,stacking parts and counting of products, composited with those parts as below

Loading parts-heating parts(three heating zone)-forming parts-cutting off parts-double workstation mechanical hand-winding parts for scraps (or crusher in line)-products conveyor double station.

Fully automatic mechanical hand PS foam food container making machine ,with great dependable stability,integrates the forming,cutting off,and stacking as well conveyor at the same time.

Fully automatic mechanical hand PS foam food container making machine is much convenient for operator as the humanly design.In addition,it has the feature of the bigger forming area faster speed of forming and highly automation.

The products will be collected with stacking parts and conveyed automatically via conveyor.The scraps will be winded or crushed in line also.

The more energy will be saved ,the safety of operator will be enhanced,but the cost of running machine will be economized.

The mechanical hand of machine could be adjusted to move up and down,front and back,using the electronic adjustment control,to meet the different needs of molds with various sizes,and the suction cup of mechanical hand could be added or reduced as the real operations to meet the needs of final products.

Q: Why you choose our company?

1,Founded in 1998.We set up a company which specially made EPE fruit net machine and knotless net extrusion line.Have over 20 years with strong experience and advanced technique.

2,we are factory direct sale ,provide you Best Quality and Service with Reasonable price.

3,We pass strict quality inspection process, each link of production equipment strict examination records, ensure the quality of the equipment.

4,The EPE foam sheet produced by our EPE foaming machine has "high foaming ratio and light weight". giving customers a greater competitive advantage in the market.

5,The equipment has a high degree of automation.They work stably and have a low failure rate. The main electrical parts are all well-known brands from China and foreign countries.The equipment includes automatic material feeding, automatic alarm for material shortage, automatic hydraulic screen changer.

6,The customers can see the machine testing or visit our customers’ factories before they decide to buy. After they pay the down payment, before shipment, the customers can come to check the machine testing. only after the machine makes perfect products which meet the customers’ requirement will they pay the balance.

7,Training how to instal the machine, training how to use the machine. Engineers available to service machinery overseas.Email:info@sgmyt.com

8,We have after-sale offices in some countries such as India, Brazil to offer customers training and the best after-sale service.we offer 24-hour failure declaration and come up with solutions for customers in the shortest time.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Longkou city, Shandong province, you can fly to Yantai or Qingdao airport, Yantai airport is nearer than Qingdao airport.When you confirm flight No. and time, please feel free to contact us, then we will pick up you on time.

Q: What's the trade term and payement term?

A: 30% or 50% T/T before production; Paid in full before shipment.

Q: Will you send the equipment to us directly after completion

A: After the completion of the equipment,you must first come to the acceptance,confirm that there is no problem before delivery