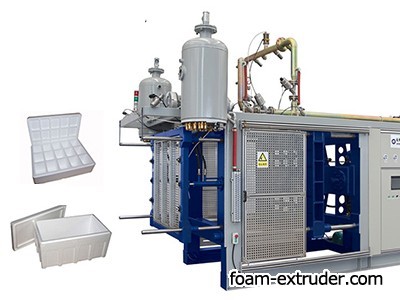

EPS Shaping Moulding Machine Main Feature:

1, combined with the high-quality characteristics of Europe, Japan and China Taiwan and other models, widely used;

2, molded foam products with low water content, low energy consumption of equipment, short production cycle, product size and stability;

3 interchangeable types of mold, equipment compatibility, saving tooling costs;

4, the frame is welded steel hollow shape, high strength, good stability;

5, after the failure of high-temperature annealing chassis welding heat treatment, the use of imported CNC machining center, bottom fine sand-blasting, galvanizing and overall surface paint, high corrosion resistance;

6, using advanced multi-cylinder hydraulic clamping systems, clamping fast, strong clamping;

7, the use of advanced central energy distributor, the equilibrium vapor pressure stable;

8, high-efficiency vacuum cooling with a spray nozzle, independent drainage system, greatly reducing the vacuum time;

9, pressure feed, advanced sensors to control quantity and density;

10, fully automatic computer control system, color touch-screen control, simple operation;

| DES |

Unit/ item |

HR500 | HR900 | HR1300 | HR1500 | HR2000 |

| Mold size | mm | 1200×1000 | 1400×1200 | 1600×1350 | 1800×1530 | 2000×1750 |

| Product size | mm | 1060×810×300 | 1230×1030×300 | 1480×1180×300 | 1560×1360×300 | 1780×1580×300 |

| Mold open distance | mm | 200-1300 | 200-1300 | 200-1300 | 200-1300 | 200-1300 |

| Steam consumption | Kg/cycle | 7 | 9 | 10 | 11 | 13 |

| Vacuum pump capacity | m3/h | 165 | 230 | 280 | 180 | 280 |

| Power | KW | 11 | 13.5 | 16 | 19.6 | 23 |

| Outsize | mm | 4850×1860×3900 | 5100×2160×4000 | 5300×2250×4200 | 5400×2550×4600 | 5500×2800×4850 |

| Weight | kg | 4150 | 4300 | 4500 | 5000 | 6800 |